Scientifically validated cooking instructions: three steps to safety

Any food product cooked by consumers – from frozen peas to sausages to whole turkeys – may present third-party food safety risks to the manufacturer. Natasha Burton, Head of Cooking Instructions at Leatherhead Food Research, says rigorous testing of on-pack instructions is central to risk mitigation.

To ensure microbiological safety, cooked food products must achieve a core temperature that is hot enough for long enough. The Food Standards Agency (FSA) advises consumers to cook food until it holds a temperature of 70°C for two minutes. Alternative time-and-temperature combinations, such as 75°C for 30 seconds, can provide the same level of safety assurance.

However, research shows that consumers rarely use a food thermometer, and most rely on the cooking instructions on food packaging*. Food manufacturers have a responsibility to ensure their cooking instructions consistently and repeatably result in safe, ready-to-eat products. Yet variations in domestic cooking equipment make this a complex task.

Here at Leatherhead our dedicated cooking instructions laboratory was recently accredited to ISO/IEC 17025:2017 (general requirements for the competence of testing and calibration laboratories) for the ninth consecutive year. We operate as a UKAS accredited testing laboratory (no. 9365) and there are three main phases to any cooking trial that we handle:

1. Checking and calibrating cooking equipment

Our accreditation encompasses cooking instructions testing using domestic equipment including microwave ovens, thermal and convection ovens, hobs, grills, deep fat fryers, and air fryers. To ensure the integrity of test results, all equipment must be accurate and reliable. We account for any disparities between different models of the same device type (e.g., wattage, capacity) and check the performance of all devices before cooking begins. Equipment used for measuring (e.g., balances and thermocouples) is also calibrated.

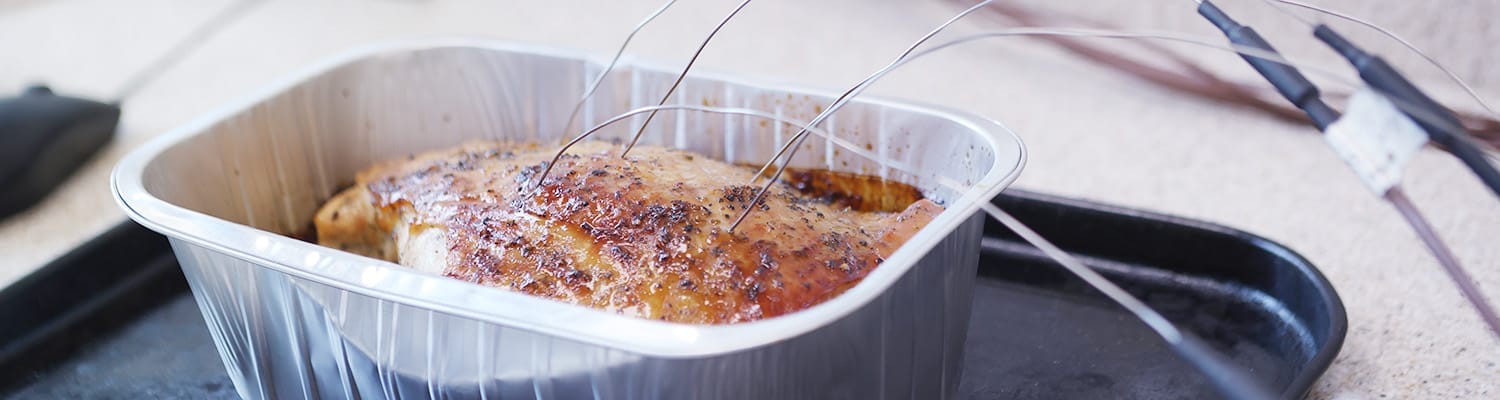

Food samples supplied for testing are checked to ensure they represent commercial products’ weight, shape, and ingredient composition. For products such as ready meals which are cooked in the tray, packaging must be representative of that used for the commercial product too.

2. Generating or verifying cooking instructions

Cooking instructions are generated or verified using a series of trials which allow each stage of the cooking process to be refined. Measuring core temperature during cooking (the in-cook temperature), as well as after cooking, plays an important role here, providing a better understanding of how the product heats. This enables more precise determination of the optimum time-and-temperature combination for a given product. For instance, a short, hot cook may be best for some products whereas others will benefit from a lower cook temperature over a longer period.

Our laboratory accreditation covers in-cook temperature measuring techniques as well as cooking instructions testing. Having conducted more than 120,000 cooking trials since we first achieved accreditation, our food scientists are uniquely positioned to offer expert guidance on combining microbiological safety with desired sensory characteristics.

3. Validating cooking instructions

Once we devise the optimum cooking process for a given product, we repeat it multiple times to validate the results, documenting outcomes. This is critical for demonstrating consistency and repeatability, which together confirm the reproducibility of results in consumer settings.

It’s important to note that the need to ensure safety doesn’t only apply to products containing meat, fish, or poultry. Non-animal-based products are less frequently associated with pathogenic hazards, but it doesn’t mean they are risk-free. Recent examples of Listeria outbreaks associated with frozen vegetables and E. coli incidents linked to falafels underline this point. Such cases reinforce the importance of scientifically validated cooking instructions for any product cooked by consumers.

The regulatory landscape for cooking instructions

UK food labelling laws require clear cooking instructions on the packaging of foods which must be cooked before consumption. The British Retail Consortium (BRC) Global Food Safety Standard specifically states that “where cooking instructions are provided to ensure product safety, they shall be fully validated to ensure that when the product is cooked according to the instructions, a safe, ready-to-eat product is consistently produced”.

Several international markets, including the EU, United States, Canada, Australia and New Zealand, and Japan, have similar mandates. Some retailers also have policies specifying that suppliers of their own brand produce should use scientific methods for cooking instructions development.

If you need cooking instructions for a new or reformulated range, or want to add a different cooking method to an existing product label, Leatherhead can help. Our cooking instructions generation and verification services include validation as standard, and methods can be aligned with specific retailer protocols. Find out more about our cooking instructions services or contact the team directly on [email protected]

* Research was conducted online on behalf of Leatherhead Food Research, December 22-23 2022. Total sample size was 2,077. The figures have been weighted and are representative of all UK adults.